Table of Contents

Full capacity in-house lab

Our office is equipped with a full-capacity dental lab and lab technicians. This is one thing that differentiates us from other offices. Most dentist offices have to send their cases out to a dental lab for the fabrication of the restorations. A few offices have a lab with limited capacity. There are certain advantages and benefits in service quality from having such an in-house lab because the whole process is under our control.

Quality control

The whole manufacturing process is closely supervised by the doctor. From the material choice to the final inspection, every step of fabrication is discussed with and guided by the doctor. Your teeth will be made under the same roof under the doctor’s scrutiny. No overseas lab. No uncertain materials. Your restoration is manufactured all within the office.

Individualized service

Service here is first-class with personal care because we know that every dental case is unique and different. Often, the technicians’ eyes and hands are needed chair-side for the best results. For example, when your tooth color and shape are being determined, you will get help directly from the technician who is responsible for fabricating your restorations. Most dental offices communicate with their lab by prescription and rarely give you a chance to talk to the technicians; But at our office, we provide direct contact even between you and the technician so you can tell them how you want your final restoration to look.

Expedited service

Immediate repair is available for those who are in urgent need. Usually, if a prosthetic breaks, you would need to drop off your prosthetic and wait a few days for it to be shipped and fixed. An advantage of having an in-house lab is that there is no time wasted on shipment, allowing for some prosthetics to be restored even in one day. Your restoration can be made much quicker and most importantly, for much cheaper.

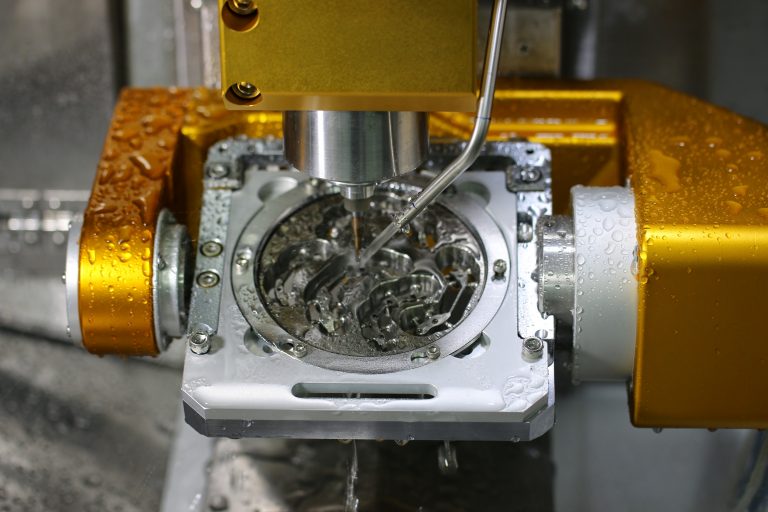

Accuracy and precision

The manufacturing of dental restorations is being digitized rapidly. Our lab is equipped with all up-to-date digital devices for the best possible accuracy and precision – down to the micrometer – which is now the norm in digital manufacturing. The traditional, manual way of fabrication is quickly becoming obsolete and we are a front-runner in the use of digital dentistry.

Integration technology

Some amazing lab technologies merge clinical data (information gathered by the doctor), with lab software. Photos or scans of your mouth taken in the clinic can be transferred to the lab to design your smile. Then, the lab will print out mock restorations of your teeth to test out in your mouth. This allows you to envision and design the final restorations in your mouth, even before you start your treatment.

State of the art CAD/CAM and qualified technicians

Computer Aided Design and Computer Aided Manufacturing systems are used to fabricate our dental restorations. Continuous update on hardware and software is required to maintain its state of art fabrication system. Among dental technicians only selected number of technicians have expertise on dental CAD/CAM because it requires massive training in both traditional art and technology.